Taiwan's Lampholder, Socket, Switch Makers Hold Global Advantage

Sep 30, 2004 Ι Industry News Ι Lighting & LEDs Ι By Quincy, CENS

Lampholders, sockets, and switches are standard components of all electric lamps, not only connecting, transmitting, and controlling power but also playing key roles in safety and performance. Without these parts, there could be no lamps as we know them today.

"Quality is the top priority for these parts, which are to a lamp what a heart is to a human being, " states Derek Lin, chairman of Golo Chang Co., Asia's most comprehensive supplier of lampholders.

As with producers in many other industries, Taiwan's makers of lampholders, switches, and sockets face fierce price competition from rivals in countries-especially mainland China--with lower production costs. Despite this difficulty, the island's manufacturers in the line are doing very well. Most of them, in fact, are having to expand capacity to meet strong demand from lamp assemblers in mainland China and elsewhere.

Suppliers have to find their competitive niche, and for Taiwan it is the offering of a very comprehensive range of products along with small-batch, large-variety production. Some manufacturers concentrate on niche products; others, especially newcomers to the line, focus on the development of innovative products with new functions.

Most of the island's companies in the line have also worked out a division-of-labor manufacturing scheme that spans the Taiwan Strait. This gives them added flexibility in the global competition.

Cross-Strait Division of Labor

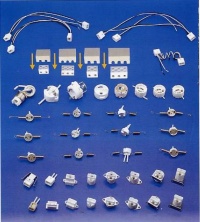

Golo Chang is one of the largest and most comprehensive suppliers of lampholders, switches, and dimmers in Taiwan, offering more than 300 product items that make up a one-stop-shopping catalog.

The ISO-9001-certified company was established in 1979 and now operates a 30-worker plant in Taiwan as well as an integrated factory in Guangdong Province, mainland China, which employs 800. The Taiwan facility is responsible for making mostly small-batch, large-variety items for domestic and export sale, while the mainland base produces for sale in mainland China and other countries.

Together, the two plants have an annual capacity of more than 120 million sockets, holders, and switches, all of which meet CE, UL, T-Mark, CSA, and VDE quality and safety standards. This makes Golo Chang a leading global supplier in its field.

The company has the capability it needs to develop universal lamp holders for various lighting sources including halogen, energy-saving, fluorescent, and incandescent bulbs and tubes, as well as a comprehensive range of sockets, switches, and dimmers that meet United States, Japanese, EU, European, and United Kingdom specifications. The products are made of a wide range of materials, including ceramics, engineering plastic, and bakelite.

Chairman Lin says that Golo Chang's insistence on high quality has won the company long-term customers around the world. He also reports that its ISO-9001 certification process was carried out by experts from UL in the U.S. instead of by the local branch of a foreign certification body.

The company invests an average of over NT$20 million (US$585, 000 at NT$34.2:US$1) every year into mold and die tooling and the development of 30 new items. Lin himself heads up the R&D department, which carefully watches over the development progress of all kinds of new lighting sources and constantly develops new models of his products for manufacturers to use in designing their lamps.

The chairman says that his company receives the latest information on lighting sources from lighting-source and lamp manufacturers around the world, allowing it to stay in the vanguard of product development.

"We have to make new sockets and holders simultaneously with, or even before, the introduction of a new lighting source to the market. This gives the lighting manufacturers a period of preparation in the development of new models, " Lin comments. "Golo plays the role of a pioneer in the lamp-making line, and we've developed over 40 internationally patented items that lead our counterparts globally."

Building on its success in the lampholder, socket, and switch business, the company recently decided to pour about US$4.5 million into a new plant for the production of lamp bodies and accessories made of the new "Tech Clay, " an environment-friendly, all-natural material that can replace polyresin. Lamp parts and accessories made of Tech Clay, Lin asserts, can biodegrade within about three years after disposal. Products made of this innovative material are also more durable, more heat-resistant, and cost less than polyresin, and they also have zero toxicity.

Halogen the Key Word

Another leader in the industry is Sharp Socket Industrial Co., which concentrates on the development and production of halogen-lamp holders and offers the most comprehensive line of such products in Taiwan.

The company operates two plants, one in Taiwan and the other (set up in 2002) in mainland China. Each has 50 workers, and together they turn out about two million holders per month. Sharp Socket also designs and manufactures mini tracklights and ceiling lights with halogen lighting sources.

The company now offers more than 200 models of halogen-lamp holder, and develops another four or five items per year. Almost all of its products are exported to the U.S. and Canada, and are certified by UL, CUL, CE, and VDE.

According to chairman Yen Yung-cheng, Sharp Socket is known around the world for provision of the highest level of product quality and the fastest delivery. All of its holders, he explains, use the best-quality springs made of high-grade steel, which can endure continuous high temperatures of up to 400 degrees. Ordinary springs are good only up to 280 degrees.

Yen notes that the high temperatures generated by halogen bulbs can gradually reduce the flexibility of springs in lamp holders and sockets, leading eventually to the breakage of the parts to which they connect.

He is able to achieve short delivery times, Yen claims, thanks to well-managed parts procurement and inventory systems, unmatched production efficiency and flexibility, and outstanding product design that reduces the number of parts and of production processes.

The chairman says that his company is using its strong development capability to develop a series of holders for the latest CDM-R111 halogen bulbs produced by Philips (Yen insists that in addition to improved structure and styling, his holders are priced at only half as much as similar products made by BJB of Germany) and a PL-H compact fluorescent lamp featuring a 9, 000-lumen output, good color rendition, and dimming and instant-on functions.

No-Weld Switch

Tarweed Enterprise Co., a newcomer to the line, has moved into the lamp switch business with the aim of using its strong development and innovation capability to assure the profitability of its Taiwan operations.

The company's first product is an innovative weld-free rocker switch for use with consumer-electronic products, lamps, and home appliances. A specially designed wire socket allows the new rocker switch to eliminate all time-consuming welding and other processes that are normally needed to install switches on lamps, surge protectors, and other appliances/devices. With the new product, all the assembler has to do is plug the 1.2mm copper wires into the socket.

A senior Tarweed official says that the new switch will greatly cut the cost of labor and time for finished-product manufacturers. Also, he claims, it is safer than welded counterparts.

The new product has been patented in Taiwan, mainland China, Germany, and the U.S. Its UL certification is pending, and is expected to be awarded soon.

Li Rong-tsung, the company's sales manager, is optimistic about the new rocker switch, expecting it to be widely adopted by manufacturers throughout the world to meet the demands of big-volume production. "The market for such a rocker switch will be unlimited, " he asserts, "and Tarweed's strong R&D department will constantly develop new items to further expand our market share." (Aug. 2004)

"Quality is the top priority for these parts, which are to a lamp what a heart is to a human being, " states Derek Lin, chairman of Golo Chang Co., Asia's most comprehensive supplier of lampholders.

As with producers in many other industries, Taiwan's makers of lampholders, switches, and sockets face fierce price competition from rivals in countries-especially mainland China--with lower production costs. Despite this difficulty, the island's manufacturers in the line are doing very well. Most of them, in fact, are having to expand capacity to meet strong demand from lamp assemblers in mainland China and elsewhere.

Suppliers have to find their competitive niche, and for Taiwan it is the offering of a very comprehensive range of products along with small-batch, large-variety production. Some manufacturers concentrate on niche products; others, especially newcomers to the line, focus on the development of innovative products with new functions.

Most of the island's companies in the line have also worked out a division-of-labor manufacturing scheme that spans the Taiwan Strait. This gives them added flexibility in the global competition.

Cross-Strait Division of Labor

Golo Chang is one of the largest and most comprehensive suppliers of lampholders, switches, and dimmers in Taiwan, offering more than 300 product items that make up a one-stop-shopping catalog.

The ISO-9001-certified company was established in 1979 and now operates a 30-worker plant in Taiwan as well as an integrated factory in Guangdong Province, mainland China, which employs 800. The Taiwan facility is responsible for making mostly small-batch, large-variety items for domestic and export sale, while the mainland base produces for sale in mainland China and other countries.

Together, the two plants have an annual capacity of more than 120 million sockets, holders, and switches, all of which meet CE, UL, T-Mark, CSA, and VDE quality and safety standards. This makes Golo Chang a leading global supplier in its field.

The company has the capability it needs to develop universal lamp holders for various lighting sources including halogen, energy-saving, fluorescent, and incandescent bulbs and tubes, as well as a comprehensive range of sockets, switches, and dimmers that meet United States, Japanese, EU, European, and United Kingdom specifications. The products are made of a wide range of materials, including ceramics, engineering plastic, and bakelite.

Chairman Lin says that Golo Chang's insistence on high quality has won the company long-term customers around the world. He also reports that its ISO-9001 certification process was carried out by experts from UL in the U.S. instead of by the local branch of a foreign certification body.

The company invests an average of over NT$20 million (US$585, 000 at NT$34.2:US$1) every year into mold and die tooling and the development of 30 new items. Lin himself heads up the R&D department, which carefully watches over the development progress of all kinds of new lighting sources and constantly develops new models of his products for manufacturers to use in designing their lamps.

The chairman says that his company receives the latest information on lighting sources from lighting-source and lamp manufacturers around the world, allowing it to stay in the vanguard of product development.

"We have to make new sockets and holders simultaneously with, or even before, the introduction of a new lighting source to the market. This gives the lighting manufacturers a period of preparation in the development of new models, " Lin comments. "Golo plays the role of a pioneer in the lamp-making line, and we've developed over 40 internationally patented items that lead our counterparts globally."

Building on its success in the lampholder, socket, and switch business, the company recently decided to pour about US$4.5 million into a new plant for the production of lamp bodies and accessories made of the new "Tech Clay, " an environment-friendly, all-natural material that can replace polyresin. Lamp parts and accessories made of Tech Clay, Lin asserts, can biodegrade within about three years after disposal. Products made of this innovative material are also more durable, more heat-resistant, and cost less than polyresin, and they also have zero toxicity.

Halogen the Key Word

Another leader in the industry is Sharp Socket Industrial Co., which concentrates on the development and production of halogen-lamp holders and offers the most comprehensive line of such products in Taiwan.

The company operates two plants, one in Taiwan and the other (set up in 2002) in mainland China. Each has 50 workers, and together they turn out about two million holders per month. Sharp Socket also designs and manufactures mini tracklights and ceiling lights with halogen lighting sources.

The company now offers more than 200 models of halogen-lamp holder, and develops another four or five items per year. Almost all of its products are exported to the U.S. and Canada, and are certified by UL, CUL, CE, and VDE.

According to chairman Yen Yung-cheng, Sharp Socket is known around the world for provision of the highest level of product quality and the fastest delivery. All of its holders, he explains, use the best-quality springs made of high-grade steel, which can endure continuous high temperatures of up to 400 degrees. Ordinary springs are good only up to 280 degrees.

Yen notes that the high temperatures generated by halogen bulbs can gradually reduce the flexibility of springs in lamp holders and sockets, leading eventually to the breakage of the parts to which they connect.

He is able to achieve short delivery times, Yen claims, thanks to well-managed parts procurement and inventory systems, unmatched production efficiency and flexibility, and outstanding product design that reduces the number of parts and of production processes.

The chairman says that his company is using its strong development capability to develop a series of holders for the latest CDM-R111 halogen bulbs produced by Philips (Yen insists that in addition to improved structure and styling, his holders are priced at only half as much as similar products made by BJB of Germany) and a PL-H compact fluorescent lamp featuring a 9, 000-lumen output, good color rendition, and dimming and instant-on functions.

No-Weld Switch

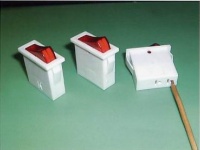

Tarweed Enterprise Co., a newcomer to the line, has moved into the lamp switch business with the aim of using its strong development and innovation capability to assure the profitability of its Taiwan operations.

The company's first product is an innovative weld-free rocker switch for use with consumer-electronic products, lamps, and home appliances. A specially designed wire socket allows the new rocker switch to eliminate all time-consuming welding and other processes that are normally needed to install switches on lamps, surge protectors, and other appliances/devices. With the new product, all the assembler has to do is plug the 1.2mm copper wires into the socket.

A senior Tarweed official says that the new switch will greatly cut the cost of labor and time for finished-product manufacturers. Also, he claims, it is safer than welded counterparts.

The new product has been patented in Taiwan, mainland China, Germany, and the U.S. Its UL certification is pending, and is expected to be awarded soon.

Li Rong-tsung, the company's sales manager, is optimistic about the new rocker switch, expecting it to be widely adopted by manufacturers throughout the world to meet the demands of big-volume production. "The market for such a rocker switch will be unlimited, " he asserts, "and Tarweed's strong R&D department will constantly develop new items to further expand our market share." (Aug. 2004)

©1995-2006 Copyright China Economic News Service All Rights Reserved.