Enjoying Glowing Prospects

Mar 26, 2004 Ι Industry News Ι Lighting & LEDs Ι By Ken, CENS

Compared with indoor lighting equipment, outdoor equipment is made with more sophisticated technology as they have to fight humidity and dramatic temperature changes, and must also be able to go on and off automatically. Happily enough for makers, higher prices can be asked for these more sophisticated wares.

Most of Taiwan's outdoor-lighting manufacturers have overcome technical difficulties to achieve these requirements, which come under the International Protection (IP) ratings covered in Australian Standard AS1939. The system uses a two-digit code to specify the particle and water resistance of a luminaire, with the first digit indicating the degree of protection of the model's interior mechanism from the ingress of solid foreign objects, and the second indicating the degree of protection of the interior from the ingress of water.

In Taiwan, the non-profit organization Taiwan Electric Research & Testing Center is authorized to issue IP certificates to manufacturers passing its examinations. According to the center, most of the island's products are qualified with rating four to six of the seven-grade list, seven being the highest rating, one the lowest.

Local manufacturers say that the island's outdoor-lighting industry was kicked off around 20 years ago, making items specifically for businesses. Around five years ago, many moved into the making of home-use models, for which demand has since increased considerably.

Many of them have moved production to mainland China in pursuit of lower production costs, engaging primarily in large-batch production. Those still producing at home in Taiwan have developed various tailor-made products for small-volume, large-variety manufacture.

A Grand Endeavor

Arthur Wang, general manager of Grandlite Energy-Saving Technology Co., Ltd., feels that Taiwanese suppliers must now enhance their after-sales service and distribution channels in the face of the competitive threat from mainland Chinese rivals, as they have already considerably improved manufacturing quality and continue to do so.

Grandlite has opened a warehouse, a branch office, and sales outlets in the United States, its major market. "All services and support come directly from our operations there, eliminating time-wasting communications through middlemen, " Wang asserts. Here too, however, mainland China rivals are closing in. "A lot of the mainland's suppliers have improved their English ability and are now opening branches in major markets, " he says.

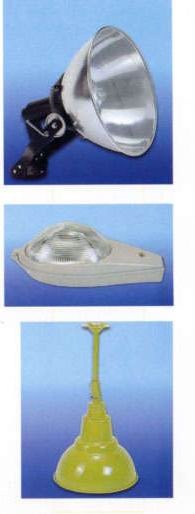

Grandlite is a high-standard manufacturer of outdoor high-intensity discharge (HID) lighting equipment for heavy-duty applications such as for warehouse, highway, parking lot, and factory lighting purposes. Production in this line accounts for 90% of the firm's output.

Most of the company's production equipment is qualified under the IP65-class standard, and also have certifications from the Taiwan Electric Research & Testing Center, according to Wang.

The company began business around 20 years ago with emphasis on indoor lighting equipment such as desk lamps, downlights, and bathroom lamps. It shifted into the outdoor-lighting sector in 1992 because of crowding in the indoor-lamp market, in which lower-cost mainland Chinese suppliers had risen to snatch away more and more business from Taiwanese rivals.

"Compared with indoor lamps, " Wang states, "outdoor lamps require higher-level technology to make, making them more valuable than indoor lamps." His company spent tens of millions of NT dollars on equipment as soon as it decided to enter outdoor-lamp manufacturing. Also, it set up comprehensive training programs and invited specialists from outside to acquire the very latest in production know-how.

Wang's company did not have much difficulty entering the new segment, he says, as it also bought outdoor-lighting models from importers while it was producing it at the same time, a measure Wang believed could help his company more quickly grasp the necessary production know-how. The models his company acquired from local importers targeted the domestic market whereas its self-made models were for export. "At that time, all domestic regulations on outdoor lamps were biased toward imported items, " he explains.

Importantly, the company had already acquired the capability to test its lamps for waterproofing, in accordance with the UL standard, in 1990.

In 1997, Grandlite elevated its technology and moved into the production of HID lighting equipment, which is much more complicated to make as the items incorporate electronic ballasts. "Lighting manufacturing 's much more complex when the manufacturing involves electronic ballasts, because ensuring the proper working of lamps and ballasts is always a technical challenge, " Wang explains.

Like other local suppliers in this line, Wang's company was not able to sell its products in the home market until just recently, when the government revised the island's Fair Trade Act to allow qualified domestically made equipment to compete with foreign-made equipment, according to Wang.

But even though his company is a qualified supplier, the domestic market is not lucrative. Wang says lighting always accounts for only a fraction of the spending by local construction companies on their construction projects. "Civil engineering usually represents 80% of their spending, and electrical as well as machinery engineering accounts for the remaining 20%. Lighting accounts for barely 1% of the spending on electrical and machinery engineering, " he estimates.

Sunny Days for Those With Shining Technology

For suppliers of lighting equipment controlled by electronic sensors, like Aurum Electronics Co., the best way to cope with the threat posed by price-undercutting rivals in lower-cost production areas is to introduce added-value models highlighting friendly electronics controllers such as timers and sensors.

The company is one of the few lighting equipment suppliers in Taiwan specializing in solar lighting and sensor lighting equipment. It has produced sensors since it was established in 1985 and began applying the devices to lighting in 1990.

According to the company's vice president Eric Hsieh, the company's business has increased 15% over the past few years. "That's because we have added many valuable functions to lighting equipment. Most outdoor lighting equipment underscores good looks while ours attract consumers with humanized functions such as timers and sensors to conserve electricity, " he says.

Hsieh company's 20-some engineers are developing sensor lighting equipment which can be remotely controlled by connecting with the Internet.

Currently, Aurum's sensor device has a minimum detecting radius of 10 meters and maximum radius of 20 meters as well as minimum detecting angle of 120 degree and maximum angle of 360 degree depending on product class. Aurum has mostly applied its sensors to home-use outdoor lamps whose power consumption ranges from 60 watts to 100 watts.

Although the company now has a good business with its sensor lighting equipment, it had a hard start. When the company decided to apply its sensor to lighting equipment from burglary-proof monitors, it hoped to always focus on the supply of the electronics devices. However, lighting-equipment suppliers the company contacted were not interested in its cooperation proposals. "The reason was that home-used sensor lamps were not popular in the United States at that time. The vast American market always decided what Taiwanese lighting suppliers should make, not we decide what it should take, " Hsieh laments.

Aurum had no choice but begin to make lighting equipment on its own and focused on European market. The company, Hsieh reported, has come by lucrative orders since then thanks to its price advantage and steady market. Although there are many suppliers of sensor-type outdoor lamps, Hsieh analyzes that the well developed electronics industry in Taiwan has enabled local sensor suppliers to make better products than do European suppliers.

In spite that the U.S. market has begun accepting sensor-type lighting equipment, the market, Hsieh notes, has been monopolized by American suppliers. He analyzes that the most prominent difference between American consumers and European consumers is that the former prefers press-formed lighting equipment to die-cast equipment whereas the latter is vice versa. However, the company successfully penetrated the American market of press-formed lighting equipment in 1999 and this type of equipment now accounts for around 30%, or 250, 000 units a month, of the company's total output. In order to cater to American consumers, the company makes its press-formed lighting equipment with copper material.

Die-casting capability is Aurum's another upside in the manufacturing, according to Hsieh. He claims that his company is the only Taiwanese lighting manufacturer capable of making both sensors and die-casting pieces. "Both capabilities enable us to well control production costs, quickly introduce new products and maintain good quality, " he says. In 1992, the company transplanted its die-casting production to mainland China. Today, it makes sensors and die-casting pieces at the 10, 000-square-meter facility.

Aurum has begun applying stainless steel and plastic materials to the body of its lighting equipment to cater to market trend. Hsieh points out that European consumers began accepting equipment whose body is made of stainless steel since 1998 and his company developed this type of lighting equipment shortly after.

The company's solar outdoor lamps are also equipped with its sensors, making them an efficient equipment which turn on only when darkness falls. The company has recently increased output of the lamps to 70, 000 systems a month from previous 40, 000 systems. So far, it has introduced around 30 models of the lamp and each comes with a five-year warrant. Non-solar lamps now account for some 200, 000 of the company's total monthly output. Overall, the company's lamps are qualified with the IP44 and 55 standards.

Europe takes 60% of the company's total annual shipments, Australia takes 20%, Japan 15%, and the United States 3%. Over the past few years, the company's annual revenue has averaged US$15 million. Hsieh is optimistic about his company's business prospects, saying that more and more retailers are passing by importers to make deals with manufacturers directly, increasing his company's business opportunities.

Sensitive to Market Needs

For Bennett Chuang, chairman of Georlin Technology Co., Ltd., another supplier of sensor-type outdoor lamps in Taiwan, the best strategy to overcome the competition is to enhance not only product quality but also after-sales services. He opened his business as a supplier of sensor scanners and burglar-proof lamps some 10 years ago; his company still offer components for the lamps it offered at that time today.

"Continuous logistic supports of components for any types of our lamps make them feel easy with being our long-term customers although the fact is that our customer seldom use a lamp too long whether it is in good condition or not, " Chuang elaborates.

Now, the company has applied its infrared-ray sensors to garden-engineering lamps to make them power-conservative products. Its lamps have acquired TUV, GS and UL approvals, which Chuang says put much stricter requirements on quality than do IP standards. "IP does not fit sensors because it does not have an adequate regulation on the devices, " Chuang says.

Although spending on these internationally recognized approvals is costly, Chuang says the spending is worthy. "There are seven sensor suppliers at home, but most of them have transplanted to mainland China or focused on only few markets with one or two approvals, " he explains.

Good quality has won the company many orders from the military, schools, airports, warehouse operators and the Taipei Rapid Transit Co. at home. According to Chuang, the Ministry of National Defense has adopted his company's burglar-proof sensor lamps and the special district around the Presidential Office Building is the first domestic site to use his company's LER2 300/500W sensor lamps. Half of its equipment is for exports.

Chuang points out that lamps like his company's must use durable materials and surface treatments so that they can serve long. His company uses tempered glass and engineering plastic to make its lamp and sensor cases as well as coats them with erosion-resist painting. "To control quality and costs as well as maintain steady supply, we make lamps on our own, " Chuang says.

His company's sensor has an average detection distance of 10 meters and regular 120-degree detecting angle. They go into lamps with power specifications ranging from three voltages, six voltages, 12 voltages, 24 voltages, 110 voltages and 220 voltages. While scanning moving objects, the company's sensors record at the same time. At day time, the lamps do not light on, making them power-conservative equipment.

Chuang's company has rolled out types that can be remotely controlled by third-generation handsets or notebook computers through the Internet protocol.

Chuang is optimistic about the future of his company's business, saying that world market of sensor-type outdoor lamps has grown at double pace over the past few years.

Prospects Rising

Rise Lighting Co., Ltd. Branched into outdoor-light production from the indoor-lamp sector around six years ago. Its focus has been on lamps that beautify buildings at night, especially spotlights. The company's vice general manager, C.B. Hung, points out that the most decisive element to win orders in this segment is light design.

"For other outdoor lamps, giving off an even brightness perhaps is the primary concern. But our lamps emphasize brightness layers, " Hung stresses. Compared with normal outdoor lights for general purposes such as street lamps and garden lamps, lamps for beautifying buildings command higher profits as a result of taking much more efforts on light aesthetics, Hung says.

Although outdoor lamps now represent only around 10% of the company's annual revenue, Hung believes this portion will increase sharply over the next few years. "The fact that more and more bustling cities in rising economies such as mainland China are emphasizing their prosperity by showing off their thriving looks at night time implies abundant business opportunities for our business, " Hung analyzes.

Rise's outdoor lamps, Hung stresses, try to distinguish themselves from others' by pursuing the goal of guaranteeing customers with five to 10 year of life spans as well as impressing customers with their excellent light-angle designs and structure. "We have kept improving the coating materials on our fixtures so that our fixtures can better resist erosions. Also, over the past few years we have improved our light design capability by equipping us with efficient design tools such as the Photopia software and many talents, " Hung notes. So far, most of the company's lighting equipment is qualified under the IP67 standard.

In recent years, the company has been developing LED outdoor lighting and opened a line at its mainland Chinese factory to put out LED lighting boards. Hung says LED lamps are an ideal lighting source for outdoor purpose for its power-conservation and durability merits. "So far, we have used LED lamps in some outdoor areas where maintenance and other work is difficult, such as on roofs, " Hung says.

Although mainland Chinese lighting manufacturers have made considerable progress in outdoor-lighting manufacturing in recent years, Hung emphasizes that the improvements can be compared only among them, not with manufacturers outside the mainland. "Compared with Taiwanese suppliers, their quality and design are still far behind, " Hung reports. His company branches into outdoor-lighting manufacturing out of concern that the manufacturing can pull his company out of the competition in the crowded indoor-lighting market, in which now the undercutting Chinese manufacturers have commanded a considerable share.

A Producer for All Seasons

Founded in 1963, Ming Lung Lighting Co., Ltd. Has stuck to its market-diversification strategy as a measure to keep its products profitable, according to company owner P.H. Chen. His company now specializes in high bay lighting, garden lighting, street lights, signboard lighting, sunken lights, and ground recessed lights.

The company's lighting equipment goes to most of world's important markets but mainland China. Also, the company never transplants to the mainland so that its products can keep a premium image.

Chen usually boasts his company's production quality, which is built up by its well equipped production lines and laboratory. He says his company's products are mostly qualified with IP65 standard.

The company now produces 25, 000 lighting fixtures a month based on its own designs or customers' designs. None of them is available in the market with the company's brand names. Six engineers do designs for the company's products.

Most of Taiwan's outdoor-lighting manufacturers have overcome technical difficulties to achieve these requirements, which come under the International Protection (IP) ratings covered in Australian Standard AS1939. The system uses a two-digit code to specify the particle and water resistance of a luminaire, with the first digit indicating the degree of protection of the model's interior mechanism from the ingress of solid foreign objects, and the second indicating the degree of protection of the interior from the ingress of water.

In Taiwan, the non-profit organization Taiwan Electric Research & Testing Center is authorized to issue IP certificates to manufacturers passing its examinations. According to the center, most of the island's products are qualified with rating four to six of the seven-grade list, seven being the highest rating, one the lowest.

Local manufacturers say that the island's outdoor-lighting industry was kicked off around 20 years ago, making items specifically for businesses. Around five years ago, many moved into the making of home-use models, for which demand has since increased considerably.

Many of them have moved production to mainland China in pursuit of lower production costs, engaging primarily in large-batch production. Those still producing at home in Taiwan have developed various tailor-made products for small-volume, large-variety manufacture.

A Grand Endeavor

Arthur Wang, general manager of Grandlite Energy-Saving Technology Co., Ltd., feels that Taiwanese suppliers must now enhance their after-sales service and distribution channels in the face of the competitive threat from mainland Chinese rivals, as they have already considerably improved manufacturing quality and continue to do so.

Grandlite has opened a warehouse, a branch office, and sales outlets in the United States, its major market. "All services and support come directly from our operations there, eliminating time-wasting communications through middlemen, " Wang asserts. Here too, however, mainland China rivals are closing in. "A lot of the mainland's suppliers have improved their English ability and are now opening branches in major markets, " he says.

Grandlite is a high-standard manufacturer of outdoor high-intensity discharge (HID) lighting equipment for heavy-duty applications such as for warehouse, highway, parking lot, and factory lighting purposes. Production in this line accounts for 90% of the firm's output.

Most of the company's production equipment is qualified under the IP65-class standard, and also have certifications from the Taiwan Electric Research & Testing Center, according to Wang.

The company began business around 20 years ago with emphasis on indoor lighting equipment such as desk lamps, downlights, and bathroom lamps. It shifted into the outdoor-lighting sector in 1992 because of crowding in the indoor-lamp market, in which lower-cost mainland Chinese suppliers had risen to snatch away more and more business from Taiwanese rivals.

"Compared with indoor lamps, " Wang states, "outdoor lamps require higher-level technology to make, making them more valuable than indoor lamps." His company spent tens of millions of NT dollars on equipment as soon as it decided to enter outdoor-lamp manufacturing. Also, it set up comprehensive training programs and invited specialists from outside to acquire the very latest in production know-how.

Wang's company did not have much difficulty entering the new segment, he says, as it also bought outdoor-lighting models from importers while it was producing it at the same time, a measure Wang believed could help his company more quickly grasp the necessary production know-how. The models his company acquired from local importers targeted the domestic market whereas its self-made models were for export. "At that time, all domestic regulations on outdoor lamps were biased toward imported items, " he explains.

Importantly, the company had already acquired the capability to test its lamps for waterproofing, in accordance with the UL standard, in 1990.

In 1997, Grandlite elevated its technology and moved into the production of HID lighting equipment, which is much more complicated to make as the items incorporate electronic ballasts. "Lighting manufacturing 's much more complex when the manufacturing involves electronic ballasts, because ensuring the proper working of lamps and ballasts is always a technical challenge, " Wang explains.

Like other local suppliers in this line, Wang's company was not able to sell its products in the home market until just recently, when the government revised the island's Fair Trade Act to allow qualified domestically made equipment to compete with foreign-made equipment, according to Wang.

But even though his company is a qualified supplier, the domestic market is not lucrative. Wang says lighting always accounts for only a fraction of the spending by local construction companies on their construction projects. "Civil engineering usually represents 80% of their spending, and electrical as well as machinery engineering accounts for the remaining 20%. Lighting accounts for barely 1% of the spending on electrical and machinery engineering, " he estimates.

Sunny Days for Those With Shining Technology

For suppliers of lighting equipment controlled by electronic sensors, like Aurum Electronics Co., the best way to cope with the threat posed by price-undercutting rivals in lower-cost production areas is to introduce added-value models highlighting friendly electronics controllers such as timers and sensors.

The company is one of the few lighting equipment suppliers in Taiwan specializing in solar lighting and sensor lighting equipment. It has produced sensors since it was established in 1985 and began applying the devices to lighting in 1990.

According to the company's vice president Eric Hsieh, the company's business has increased 15% over the past few years. "That's because we have added many valuable functions to lighting equipment. Most outdoor lighting equipment underscores good looks while ours attract consumers with humanized functions such as timers and sensors to conserve electricity, " he says.

Hsieh company's 20-some engineers are developing sensor lighting equipment which can be remotely controlled by connecting with the Internet.

Currently, Aurum's sensor device has a minimum detecting radius of 10 meters and maximum radius of 20 meters as well as minimum detecting angle of 120 degree and maximum angle of 360 degree depending on product class. Aurum has mostly applied its sensors to home-use outdoor lamps whose power consumption ranges from 60 watts to 100 watts.

Although the company now has a good business with its sensor lighting equipment, it had a hard start. When the company decided to apply its sensor to lighting equipment from burglary-proof monitors, it hoped to always focus on the supply of the electronics devices. However, lighting-equipment suppliers the company contacted were not interested in its cooperation proposals. "The reason was that home-used sensor lamps were not popular in the United States at that time. The vast American market always decided what Taiwanese lighting suppliers should make, not we decide what it should take, " Hsieh laments.

Aurum had no choice but begin to make lighting equipment on its own and focused on European market. The company, Hsieh reported, has come by lucrative orders since then thanks to its price advantage and steady market. Although there are many suppliers of sensor-type outdoor lamps, Hsieh analyzes that the well developed electronics industry in Taiwan has enabled local sensor suppliers to make better products than do European suppliers.

In spite that the U.S. market has begun accepting sensor-type lighting equipment, the market, Hsieh notes, has been monopolized by American suppliers. He analyzes that the most prominent difference between American consumers and European consumers is that the former prefers press-formed lighting equipment to die-cast equipment whereas the latter is vice versa. However, the company successfully penetrated the American market of press-formed lighting equipment in 1999 and this type of equipment now accounts for around 30%, or 250, 000 units a month, of the company's total output. In order to cater to American consumers, the company makes its press-formed lighting equipment with copper material.

Die-casting capability is Aurum's another upside in the manufacturing, according to Hsieh. He claims that his company is the only Taiwanese lighting manufacturer capable of making both sensors and die-casting pieces. "Both capabilities enable us to well control production costs, quickly introduce new products and maintain good quality, " he says. In 1992, the company transplanted its die-casting production to mainland China. Today, it makes sensors and die-casting pieces at the 10, 000-square-meter facility.

Aurum has begun applying stainless steel and plastic materials to the body of its lighting equipment to cater to market trend. Hsieh points out that European consumers began accepting equipment whose body is made of stainless steel since 1998 and his company developed this type of lighting equipment shortly after.

The company's solar outdoor lamps are also equipped with its sensors, making them an efficient equipment which turn on only when darkness falls. The company has recently increased output of the lamps to 70, 000 systems a month from previous 40, 000 systems. So far, it has introduced around 30 models of the lamp and each comes with a five-year warrant. Non-solar lamps now account for some 200, 000 of the company's total monthly output. Overall, the company's lamps are qualified with the IP44 and 55 standards.

Europe takes 60% of the company's total annual shipments, Australia takes 20%, Japan 15%, and the United States 3%. Over the past few years, the company's annual revenue has averaged US$15 million. Hsieh is optimistic about his company's business prospects, saying that more and more retailers are passing by importers to make deals with manufacturers directly, increasing his company's business opportunities.

Sensitive to Market Needs

For Bennett Chuang, chairman of Georlin Technology Co., Ltd., another supplier of sensor-type outdoor lamps in Taiwan, the best strategy to overcome the competition is to enhance not only product quality but also after-sales services. He opened his business as a supplier of sensor scanners and burglar-proof lamps some 10 years ago; his company still offer components for the lamps it offered at that time today.

"Continuous logistic supports of components for any types of our lamps make them feel easy with being our long-term customers although the fact is that our customer seldom use a lamp too long whether it is in good condition or not, " Chuang elaborates.

Now, the company has applied its infrared-ray sensors to garden-engineering lamps to make them power-conservative products. Its lamps have acquired TUV, GS and UL approvals, which Chuang says put much stricter requirements on quality than do IP standards. "IP does not fit sensors because it does not have an adequate regulation on the devices, " Chuang says.

Although spending on these internationally recognized approvals is costly, Chuang says the spending is worthy. "There are seven sensor suppliers at home, but most of them have transplanted to mainland China or focused on only few markets with one or two approvals, " he explains.

Good quality has won the company many orders from the military, schools, airports, warehouse operators and the Taipei Rapid Transit Co. at home. According to Chuang, the Ministry of National Defense has adopted his company's burglar-proof sensor lamps and the special district around the Presidential Office Building is the first domestic site to use his company's LER2 300/500W sensor lamps. Half of its equipment is for exports.

Chuang points out that lamps like his company's must use durable materials and surface treatments so that they can serve long. His company uses tempered glass and engineering plastic to make its lamp and sensor cases as well as coats them with erosion-resist painting. "To control quality and costs as well as maintain steady supply, we make lamps on our own, " Chuang says.

His company's sensor has an average detection distance of 10 meters and regular 120-degree detecting angle. They go into lamps with power specifications ranging from three voltages, six voltages, 12 voltages, 24 voltages, 110 voltages and 220 voltages. While scanning moving objects, the company's sensors record at the same time. At day time, the lamps do not light on, making them power-conservative equipment.

Chuang's company has rolled out types that can be remotely controlled by third-generation handsets or notebook computers through the Internet protocol.

Chuang is optimistic about the future of his company's business, saying that world market of sensor-type outdoor lamps has grown at double pace over the past few years.

Prospects Rising

Rise Lighting Co., Ltd. Branched into outdoor-light production from the indoor-lamp sector around six years ago. Its focus has been on lamps that beautify buildings at night, especially spotlights. The company's vice general manager, C.B. Hung, points out that the most decisive element to win orders in this segment is light design.

"For other outdoor lamps, giving off an even brightness perhaps is the primary concern. But our lamps emphasize brightness layers, " Hung stresses. Compared with normal outdoor lights for general purposes such as street lamps and garden lamps, lamps for beautifying buildings command higher profits as a result of taking much more efforts on light aesthetics, Hung says.

Although outdoor lamps now represent only around 10% of the company's annual revenue, Hung believes this portion will increase sharply over the next few years. "The fact that more and more bustling cities in rising economies such as mainland China are emphasizing their prosperity by showing off their thriving looks at night time implies abundant business opportunities for our business, " Hung analyzes.

Rise's outdoor lamps, Hung stresses, try to distinguish themselves from others' by pursuing the goal of guaranteeing customers with five to 10 year of life spans as well as impressing customers with their excellent light-angle designs and structure. "We have kept improving the coating materials on our fixtures so that our fixtures can better resist erosions. Also, over the past few years we have improved our light design capability by equipping us with efficient design tools such as the Photopia software and many talents, " Hung notes. So far, most of the company's lighting equipment is qualified under the IP67 standard.

In recent years, the company has been developing LED outdoor lighting and opened a line at its mainland Chinese factory to put out LED lighting boards. Hung says LED lamps are an ideal lighting source for outdoor purpose for its power-conservation and durability merits. "So far, we have used LED lamps in some outdoor areas where maintenance and other work is difficult, such as on roofs, " Hung says.

Although mainland Chinese lighting manufacturers have made considerable progress in outdoor-lighting manufacturing in recent years, Hung emphasizes that the improvements can be compared only among them, not with manufacturers outside the mainland. "Compared with Taiwanese suppliers, their quality and design are still far behind, " Hung reports. His company branches into outdoor-lighting manufacturing out of concern that the manufacturing can pull his company out of the competition in the crowded indoor-lighting market, in which now the undercutting Chinese manufacturers have commanded a considerable share.

A Producer for All Seasons

Founded in 1963, Ming Lung Lighting Co., Ltd. Has stuck to its market-diversification strategy as a measure to keep its products profitable, according to company owner P.H. Chen. His company now specializes in high bay lighting, garden lighting, street lights, signboard lighting, sunken lights, and ground recessed lights.

The company's lighting equipment goes to most of world's important markets but mainland China. Also, the company never transplants to the mainland so that its products can keep a premium image.

Chen usually boasts his company's production quality, which is built up by its well equipped production lines and laboratory. He says his company's products are mostly qualified with IP65 standard.

The company now produces 25, 000 lighting fixtures a month based on its own designs or customers' designs. None of them is available in the market with the company's brand names. Six engineers do designs for the company's products.

©1995-2006 Copyright China Economic News Service All Rights Reserved.