Taiwan-Made Masonry Tools Help Builders Around the World

Sep 30, 2004 Ι Industry News Ι Hardware & Tools Ι By Ben, CENS

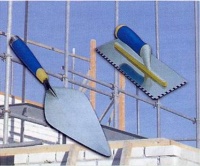

Most of the high-end professional masonry tools that Taiwan makes are exported to the industrially advanced nations' and many of the island's manufacturers in the line are constantly retooling their production equipment in order to meet the ever more stringent standards of quality-sensitive markets.

This is done to avoid price competition from rival producers in developing-economy nations' they say' who make inferior products that carry lower price tags. To maintain their reputations in upscale markets' Taiwan's manufacturers use high-grade iron and steel plates along with advanced technology to turn out their masonry tools. They focus on one-piece drop-forged trowels' for example' instead of conventional trowels with riveted handlebars.

Taiwan has five specialized makers of masonry tools' along with dozens of companies that turn out other categories of products as well as masonry tools. The specialized manufacturers do all of their production in Taiwan' feeling that the island is an ideal place to produce own-design products for professional use. They maintain in-house R&D departments that develop innovative products.

Expanding to Export

One of Taiwan's most experienced makers of masonry tools is the TUV-certified Hsiang Fu Chia Enterprise Co.' which has been in the line for over three decades. It concentrates on one-piece tools for professional instead of DIY use. "We're sticking to Taiwan for our production'" says Lu Ming-te' the company's president' "because we make only high-quality products for professional use and Taiwan is the best place for that."

Located in the central Taiwan county of Changhua' Hsiang Fu Chia takes comfort in the support it receives from peripheral industries. "There are a lot of supporting companies in related industries in central Taiwan'" Lu explains. "These include specialized producers of hardware that can meet our requirements for the supply of high-quality parts and components."

The company began exporting eight years ago' after it carried out a capacity expansion to ready itself' and now sells to major overseas markets including the United States' Australia' and Europe.

Over the past several years' Lu claims' his company's in-house R&D department has developed many innovative products along with advanced production equipment for specially designed tools.

The company concentrates on high-quality products' it says' and devotes much attention to stringent processes that assure unmarred surfaces of the iron plate that it uses to make masonry tools. "We've established unique metal-polishing skills'" Lu reports' "by adopting specially designed polishing machines which cost NT$400'000 (US$11'900 at NT$33.7:US$1) per unit. Each of these machines has been the brainchild of our talented in-house mechanical engineers' so you can't find them anywhere else."

Lu says that his firm can turn out product lines according to customer designs-and promises not to sell such products to others.

In addition to major shows in the U.S. and Europe' this year Hsiang Fu Chia will show off its latest products in Mexico. "I recently learned from old customers that Mexico is an emerging market that is worthy of development'" Lu explains. "So we evaluated the situation and decided to participate in a construction and hardware show in Mexico City this September. This will be our first time to showcase newly developed products in Latin America."

The company will also showcase products bearing its own "Hsiang Fu Chia" brand overseas for the first time at a construction and building tool show in Florida next February.

With the development of new products and new markets' Lu is confident that the company's sales will grow by 40% this year.

New Products' New Markets

Another forerunner in the development of innovative products and new markets is Ching Chang Hardware & Enterprise Co. Also based in Changhua' the company claims that it has upgraded its manufacturing skills for the production of high-quality professional tools.

Established in 1985' the company began concentrating on exports about seven years ago. "To make that transformation'" reports Ching Chang president Wu Cheng-tao' "we began employing sophisticated molds for large masonry tools that can fit the requirements of Western consumers such as those of the U.S. and some industrialized European nations."

With two decades of experience in the line' Ching Chang claims that it operates unique production processes that ensure high product quality. The steel plate that it uses' for example' is mirror polished and is subject to strict surface heat treatment and polishing processes.

"In the production process'" Wu comments' "we pay special attention to the cleaning of the surface of the steel plates to ensure that they are smooth enough. Then the plates have to undergo surface treatment' and all of the processes are carried out at our own factory."

The company has an R&D department that can develop its own innovative products' but it also welcomes custom orders based on samples supplied by the customers.

Wu claims that he is not worried about price competition from developing economies' especially mainland China' because "the producers there concentrate only on low-end products at low prices' while we turn out high-quality lines that are differentiated from inferior ones."

He is worried' though' about the rising cost of materials' including carbon steel and stainless steel. "Over the past year and a half we've seen the price of stainless steel on a rampant rise' and there seems to be no end to it'" he laments. "Many domestic manufacturers are plagued by this problem' and it has increased our production costs. With materials costs still on the rise' we're thinking about streamlining our production processes and cutting overhead to keep production costs down."

Leader of the Tool Pack

Leading Tools Industrial Co.' established in 1982' is another of Taiwan's specialized makers of high-quality artisan-use tools such as bricklaying tools and notched trowels. The company is capable of designing its own fully automated special-purpose equipment for the production of sophisticated items.

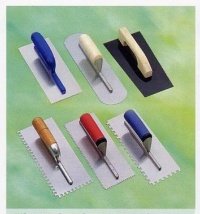

At its 35-worker plant in the Taichung Industrial Park in central Taiwan' the company turns out finishing trowels' notched trowels' brick/pointing tools' drywall/flooring/plaster tools' and other related tools.

Ever since its establishment' the company has been pursuing the advanced technology needed to design and manufacture high-trade products for sale in the advanced industrial countries. The avoidance of low-end products means that Leading Tools has never had to counter price competition from developing countries.

The company has won ISO-9001:2000 certification' and says that it turns out products in line with the latest developments in the global masonry-tool industry. Over the past few years' for example' its concentration has been on one-piece drop-forged professional trowels for upscale markets around the world. At present' 80% of its production equipment is comprised of automated special-purpose machines.

"We have the know-how we need to develop sophisticated production machinery for our own use'" states Leading Tools' president' Rick Wang. "No other domestic manufacturer can design machinery for the production of high-grade masonry tools like we can' and we cooperate with machinery manufacturers who help us realize our ideas about fabricating sophisticated production machinery."

A small-cap manufacturer' Leading Tools is devoted to boosting its competitiveness by enhancing production skills and reducing production costs. As a result' Wang contends' "Our products can rival those made in advanced industrial nations' but at a more competitive price. And although manufacturers in mainland China are capable of mass-producing similar products at lower prices-two-thirds of ours--their products are much inferior to ours in quality and reliability. That's why we've been able to stand out in the international marketplace for so long."

The company has been highlighting the quality of its products at major international hardware shows over the past several years' including those held in Cologne and Las Vegas. The products are marketed through manufacturers and DIY stores in advanced industrial countries on an original equipment/design manufacturer (OEM/ODM) basis.

Over 70% of Leading Tools' exports go the U.S. and Europe. However' Wang says' "we're keeping an eye on the emerging markets of Eastern Europe and the Commonwealth of Independent States' where we've seen increased purchasing power over the past few years."

Catering to the DIY Customer

While most of Taiwan's manufacturers in the line focus on high-grade masonry tools for the professional market' a few still concentrate on products for DIY buyers. However' even these suppliers emphasize high quality.

One of these specialists in DIY masonry tools is Ken Test Combination Products Co.' which was established in 1975 and is today one of the island's few manufacturers that specialize in making relatively small tile tools for the DIY and home-repair market.

The company's main production facility for masonry tools is located in Tatu' Taichung County' in central Taiwan. It also has three supporting plants that specialize in other types of masonry tools.

Ken Test has cooperated with the supporting plants for more than two decades; and' notes general manager Joy H. Tsai' "The quality of their products is assured' because we inspect every item that they produce before it is delivered to our factory for final assembly."

Ever since its establishment the company has focused on products that cater to the needs of the household consumer. "I've positioned my company as a maker of DIY masonry tools featuring superior convenience of use'" Tsai says. "That's why we've never involved ourselves with the production of large-sized electric tools. In this business' I think that the demand is larger for DIY tools than for professional ones."

The focus on DIY products does not' however' detract from the company's obsession with quality. "Household customers have an awareness of the quality of DIY products'" explains Tsai' "in addition to their convenience. That's why we don't neglect quality just because our products are used by home consumers rather than professional ones."

Among the range of products currently offered by Ken Test are finishing trowels' inside/outside corner tools' replacement soft/wood handle trowels' mixer and drywall tools' hammers' tile cutters' and accessories. The company says that it can roll out one or two innovative new items every year.

To assure quality' some key materials are imported from the advanced industrial countries; most of the steel plates it uses' for example' are brought in from the U.S. and Europe.

The firm's in-house R&D team is capable of designing innovative products on its own; however' Tsai concedes' "We currently sell our products to the international marketplace on an OEM basis. If customers give us samples or their original design concepts' we can develop the products in accordance with their requirements."

The company also has its own export department' and over the past few years has been participating in major international hardware and building tool shows. These include those held in Las Vegas' Chicago' and Cologne.

Such international exposure has proven worthwhile. "We won some new customers when we participated in the Las Vegas show in May this year'" Tsai reports. "The warm response we've received at these international shows indicate that our products have strong competitiveness in the industrially advanced economies." (July 2004)

This is done to avoid price competition from rival producers in developing-economy nations' they say' who make inferior products that carry lower price tags. To maintain their reputations in upscale markets' Taiwan's manufacturers use high-grade iron and steel plates along with advanced technology to turn out their masonry tools. They focus on one-piece drop-forged trowels' for example' instead of conventional trowels with riveted handlebars.

Taiwan has five specialized makers of masonry tools' along with dozens of companies that turn out other categories of products as well as masonry tools. The specialized manufacturers do all of their production in Taiwan' feeling that the island is an ideal place to produce own-design products for professional use. They maintain in-house R&D departments that develop innovative products.

Expanding to Export

One of Taiwan's most experienced makers of masonry tools is the TUV-certified Hsiang Fu Chia Enterprise Co.' which has been in the line for over three decades. It concentrates on one-piece tools for professional instead of DIY use. "We're sticking to Taiwan for our production'" says Lu Ming-te' the company's president' "because we make only high-quality products for professional use and Taiwan is the best place for that."

Located in the central Taiwan county of Changhua' Hsiang Fu Chia takes comfort in the support it receives from peripheral industries. "There are a lot of supporting companies in related industries in central Taiwan'" Lu explains. "These include specialized producers of hardware that can meet our requirements for the supply of high-quality parts and components."

The company began exporting eight years ago' after it carried out a capacity expansion to ready itself' and now sells to major overseas markets including the United States' Australia' and Europe.

Over the past several years' Lu claims' his company's in-house R&D department has developed many innovative products along with advanced production equipment for specially designed tools.

The company concentrates on high-quality products' it says' and devotes much attention to stringent processes that assure unmarred surfaces of the iron plate that it uses to make masonry tools. "We've established unique metal-polishing skills'" Lu reports' "by adopting specially designed polishing machines which cost NT$400'000 (US$11'900 at NT$33.7:US$1) per unit. Each of these machines has been the brainchild of our talented in-house mechanical engineers' so you can't find them anywhere else."

Lu says that his firm can turn out product lines according to customer designs-and promises not to sell such products to others.

In addition to major shows in the U.S. and Europe' this year Hsiang Fu Chia will show off its latest products in Mexico. "I recently learned from old customers that Mexico is an emerging market that is worthy of development'" Lu explains. "So we evaluated the situation and decided to participate in a construction and hardware show in Mexico City this September. This will be our first time to showcase newly developed products in Latin America."

The company will also showcase products bearing its own "Hsiang Fu Chia" brand overseas for the first time at a construction and building tool show in Florida next February.

With the development of new products and new markets' Lu is confident that the company's sales will grow by 40% this year.

New Products' New Markets

Another forerunner in the development of innovative products and new markets is Ching Chang Hardware & Enterprise Co. Also based in Changhua' the company claims that it has upgraded its manufacturing skills for the production of high-quality professional tools.

Established in 1985' the company began concentrating on exports about seven years ago. "To make that transformation'" reports Ching Chang president Wu Cheng-tao' "we began employing sophisticated molds for large masonry tools that can fit the requirements of Western consumers such as those of the U.S. and some industrialized European nations."

With two decades of experience in the line' Ching Chang claims that it operates unique production processes that ensure high product quality. The steel plate that it uses' for example' is mirror polished and is subject to strict surface heat treatment and polishing processes.

"In the production process'" Wu comments' "we pay special attention to the cleaning of the surface of the steel plates to ensure that they are smooth enough. Then the plates have to undergo surface treatment' and all of the processes are carried out at our own factory."

The company has an R&D department that can develop its own innovative products' but it also welcomes custom orders based on samples supplied by the customers.

Wu claims that he is not worried about price competition from developing economies' especially mainland China' because "the producers there concentrate only on low-end products at low prices' while we turn out high-quality lines that are differentiated from inferior ones."

He is worried' though' about the rising cost of materials' including carbon steel and stainless steel. "Over the past year and a half we've seen the price of stainless steel on a rampant rise' and there seems to be no end to it'" he laments. "Many domestic manufacturers are plagued by this problem' and it has increased our production costs. With materials costs still on the rise' we're thinking about streamlining our production processes and cutting overhead to keep production costs down."

Leader of the Tool Pack

Leading Tools Industrial Co.' established in 1982' is another of Taiwan's specialized makers of high-quality artisan-use tools such as bricklaying tools and notched trowels. The company is capable of designing its own fully automated special-purpose equipment for the production of sophisticated items.

At its 35-worker plant in the Taichung Industrial Park in central Taiwan' the company turns out finishing trowels' notched trowels' brick/pointing tools' drywall/flooring/plaster tools' and other related tools.

Ever since its establishment' the company has been pursuing the advanced technology needed to design and manufacture high-trade products for sale in the advanced industrial countries. The avoidance of low-end products means that Leading Tools has never had to counter price competition from developing countries.

The company has won ISO-9001:2000 certification' and says that it turns out products in line with the latest developments in the global masonry-tool industry. Over the past few years' for example' its concentration has been on one-piece drop-forged professional trowels for upscale markets around the world. At present' 80% of its production equipment is comprised of automated special-purpose machines.

"We have the know-how we need to develop sophisticated production machinery for our own use'" states Leading Tools' president' Rick Wang. "No other domestic manufacturer can design machinery for the production of high-grade masonry tools like we can' and we cooperate with machinery manufacturers who help us realize our ideas about fabricating sophisticated production machinery."

A small-cap manufacturer' Leading Tools is devoted to boosting its competitiveness by enhancing production skills and reducing production costs. As a result' Wang contends' "Our products can rival those made in advanced industrial nations' but at a more competitive price. And although manufacturers in mainland China are capable of mass-producing similar products at lower prices-two-thirds of ours--their products are much inferior to ours in quality and reliability. That's why we've been able to stand out in the international marketplace for so long."

The company has been highlighting the quality of its products at major international hardware shows over the past several years' including those held in Cologne and Las Vegas. The products are marketed through manufacturers and DIY stores in advanced industrial countries on an original equipment/design manufacturer (OEM/ODM) basis.

Over 70% of Leading Tools' exports go the U.S. and Europe. However' Wang says' "we're keeping an eye on the emerging markets of Eastern Europe and the Commonwealth of Independent States' where we've seen increased purchasing power over the past few years."

Catering to the DIY Customer

While most of Taiwan's manufacturers in the line focus on high-grade masonry tools for the professional market' a few still concentrate on products for DIY buyers. However' even these suppliers emphasize high quality.

One of these specialists in DIY masonry tools is Ken Test Combination Products Co.' which was established in 1975 and is today one of the island's few manufacturers that specialize in making relatively small tile tools for the DIY and home-repair market.

The company's main production facility for masonry tools is located in Tatu' Taichung County' in central Taiwan. It also has three supporting plants that specialize in other types of masonry tools.

Ken Test has cooperated with the supporting plants for more than two decades; and' notes general manager Joy H. Tsai' "The quality of their products is assured' because we inspect every item that they produce before it is delivered to our factory for final assembly."

Ever since its establishment the company has focused on products that cater to the needs of the household consumer. "I've positioned my company as a maker of DIY masonry tools featuring superior convenience of use'" Tsai says. "That's why we've never involved ourselves with the production of large-sized electric tools. In this business' I think that the demand is larger for DIY tools than for professional ones."

The focus on DIY products does not' however' detract from the company's obsession with quality. "Household customers have an awareness of the quality of DIY products'" explains Tsai' "in addition to their convenience. That's why we don't neglect quality just because our products are used by home consumers rather than professional ones."

Among the range of products currently offered by Ken Test are finishing trowels' inside/outside corner tools' replacement soft/wood handle trowels' mixer and drywall tools' hammers' tile cutters' and accessories. The company says that it can roll out one or two innovative new items every year.

To assure quality' some key materials are imported from the advanced industrial countries; most of the steel plates it uses' for example' are brought in from the U.S. and Europe.

The firm's in-house R&D team is capable of designing innovative products on its own; however' Tsai concedes' "We currently sell our products to the international marketplace on an OEM basis. If customers give us samples or their original design concepts' we can develop the products in accordance with their requirements."

The company also has its own export department' and over the past few years has been participating in major international hardware and building tool shows. These include those held in Las Vegas' Chicago' and Cologne.

Such international exposure has proven worthwhile. "We won some new customers when we participated in the Las Vegas show in May this year'" Tsai reports. "The warm response we've received at these international shows indicate that our products have strong competitiveness in the industrially advanced economies." (July 2004)

©1995-2006 Copyright China Economic News Service All Rights Reserved.