Taiwanese Water-Supply Equipment Makers Pursue NSF Approval

Mar 26, 2004 Ι Industry News Ι Hardware & Tools Ι By Ken, CENS

As the United States is the world's biggest buyer of water-supply equipment' and Taiwan's most important export market for such products' the island's manufacturers in the line are working hard to win the NSF approval they need to ship their goods to customers there despite the time and cost that this entails.

NSF International was founded in 1944' and its mark of approval for food' water' indoor air' and the environment is valued around the world and respected by regulatory agencies at the local' state' and federal levels. In the field of water' the organization has established standards for drinking water treatment chemicals' treatment units' municipal drinking water system components' plumbing system components' and wastewater treatment units as well as pools' spas' and hot tubs.

The water treatment chemicals subject to NSF standards include flocculants' surfactants' and disinfectants' and drinking water treatment units covered by the organization's approval include water filters' water softeners' reverse osmosis systems' distillers' and UV disinfectants. NSF also gives approval to municipal drinking water system components such as coatings' valves' pipes' water meters' and in-line devices' while affected plumbing system components include plastic pipe and fittings' faucets' valves' plumbing fixtures' metal piping' and electrical and telecoms conduits.

Suppliers wishing to sell filters' chemical feeding equipment' multiport valves' and other items for pools' spas' and hot tubs to the U.S. must also obtain the NSF mark of approval. The organization's standards are applied to wastewater treatment units such as whole-house wastewater treatment systems' filters' and pumps as well.

These required standards help to protect the health of American citizens and the quality of the American environment' even as they force water equipment providers to improve their quality. Obviously' NSF approval increases a manufacturer's chances of winning orders for his products.

The Importance of NSF

Like many other Taiwanese suppliers in the line' C.T. Chuang' chairman of Chu-chone Industrial' a company set up in 1986 to make copper plumbing parts for bathroom and kitchen hardware' fully realizes the importance of NSF certification to exporters who target the North American market. Chu-Chone won NSF approval around six years ago' thanks to a sizable investment in the adjustment of its manufacturing processes.

"Winning NSF approval is costly and takes time'" Chuang comments' "but we had to do it because it distinguishes us from our undercutting rivals in mainland China' most of which cannot meet NSF standards." The chairman reports that NSF sends specialists to inspect the manufacturing quality of applicants for the mark four times within a year' with each inspection taking at least 21 days' before granting its approval. After a manufacturer wins approval' the organization sends experts to check up on it at least once a year. When they come' Chuang notes' "You have to pay their travel expenses' which usually are not a small amount."

To win NSF qualification Chu-Chone spent tens of million of New Taiwan Dollars on production machinery and methods' including the de-leading technology needed to wash the lead out from copper pieces. This sets his company apart from most of its Taiwanese counterparts' Chuang says.

Another factor that makes Chu-Chone different from the general crowd in Taiwan is its ability to do most processing tasks on its own--which' Chuang stresses' ensures high quality. The chairman notes that the company has installed computer numerically controlled (CNC) lathes so that all of its work pieces can be cut to precise specifications.

A recent problem afflicting his industry' Chuang comments' is the 30% increase in copper prices in the international market over the past three months.

Seeking to Be Zero-Defect Producer

Another company that sees the value of NSF certification is the Shyang Yih Hardware Factory' which earned the mark last year. "NSF standards require you to cut down your defect ratio' and thus improve quality'" says the company's chairman' Hung Ruei-mu. "One advantage of having NSF approval is that it enables you to participate in contract bidding."

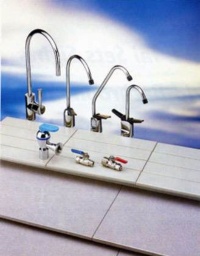

Shyang Yih produces a wide range of metal parts associated with drinking water' including ball valves' pneumatic and hydraulic connectors' quick connectors' flanges' safety valves' water gauge valves' needle valves' water inlet T-joints' ball cocks' reverse osmosis parts' and faucets.

Hung notes that the strict NSF standards require lead substances to be limited to a harmless level of under 0.025 PPM. Inspections of work pieces and sample products to ensure that the company is maintaining the required standards are not cheap' costing at least NT$300'000 (US$9'100) each. The tests are conducted at NSF's U.S. headquarters.

The company began making reverse osmosis parts and other parts for drinking-water equipment three years ago as part of its plan to break away from the crowding and intense competition in the market for hydraulic and pneumatic parts' which now are supplied mostly by mainland Chinese manufacturers. "As parts associated with drinking water require higher safety standards'" Hung explains' "their added-value must also be higher than that of hydraulic and pneumatic parts."

Parts for reverse osmosis equipment and drinking water machines currently account for 80% of the company's sales' with hydraulic and pneumatic parts making up the remaining 20%. Hung claims to supply the widest range of faucet types (encompassing almost 95% of all types available on the market)' and to be among Taiwan's top three suppliers of faucets in terms of volume.

Several of the faucets developed by Shyang Yih over the past three years are protected by patents' including one which is notable for its replaceable rubber water-control structure. This allows these faucets' unlike others' to be repaired instead of having to be replaced entirely once the water-control mechanism wears out.

Hung notes that Taiwan's manufacturers learned how to manufacture reverse osmosis parts from American suppliers' and have emerged as the world's best contract suppliers of such products. "Some suppliers in the line are coming up in mainland China'" the chairman concedes' "but they are no threat to us because their quality is still not very good."

Hung himself has invested in a factory in mainland China to supply the huge domestic market there. The mainland factory turns out 10'000 drinking water machine faucets and 10'000 reverse osmosis faucets a month. (Feb. 2004)

NSF International was founded in 1944' and its mark of approval for food' water' indoor air' and the environment is valued around the world and respected by regulatory agencies at the local' state' and federal levels. In the field of water' the organization has established standards for drinking water treatment chemicals' treatment units' municipal drinking water system components' plumbing system components' and wastewater treatment units as well as pools' spas' and hot tubs.

The water treatment chemicals subject to NSF standards include flocculants' surfactants' and disinfectants' and drinking water treatment units covered by the organization's approval include water filters' water softeners' reverse osmosis systems' distillers' and UV disinfectants. NSF also gives approval to municipal drinking water system components such as coatings' valves' pipes' water meters' and in-line devices' while affected plumbing system components include plastic pipe and fittings' faucets' valves' plumbing fixtures' metal piping' and electrical and telecoms conduits.

Suppliers wishing to sell filters' chemical feeding equipment' multiport valves' and other items for pools' spas' and hot tubs to the U.S. must also obtain the NSF mark of approval. The organization's standards are applied to wastewater treatment units such as whole-house wastewater treatment systems' filters' and pumps as well.

These required standards help to protect the health of American citizens and the quality of the American environment' even as they force water equipment providers to improve their quality. Obviously' NSF approval increases a manufacturer's chances of winning orders for his products.

The Importance of NSF

Like many other Taiwanese suppliers in the line' C.T. Chuang' chairman of Chu-chone Industrial' a company set up in 1986 to make copper plumbing parts for bathroom and kitchen hardware' fully realizes the importance of NSF certification to exporters who target the North American market. Chu-Chone won NSF approval around six years ago' thanks to a sizable investment in the adjustment of its manufacturing processes.

"Winning NSF approval is costly and takes time'" Chuang comments' "but we had to do it because it distinguishes us from our undercutting rivals in mainland China' most of which cannot meet NSF standards." The chairman reports that NSF sends specialists to inspect the manufacturing quality of applicants for the mark four times within a year' with each inspection taking at least 21 days' before granting its approval. After a manufacturer wins approval' the organization sends experts to check up on it at least once a year. When they come' Chuang notes' "You have to pay their travel expenses' which usually are not a small amount."

To win NSF qualification Chu-Chone spent tens of million of New Taiwan Dollars on production machinery and methods' including the de-leading technology needed to wash the lead out from copper pieces. This sets his company apart from most of its Taiwanese counterparts' Chuang says.

Another factor that makes Chu-Chone different from the general crowd in Taiwan is its ability to do most processing tasks on its own--which' Chuang stresses' ensures high quality. The chairman notes that the company has installed computer numerically controlled (CNC) lathes so that all of its work pieces can be cut to precise specifications.

A recent problem afflicting his industry' Chuang comments' is the 30% increase in copper prices in the international market over the past three months.

Seeking to Be Zero-Defect Producer

Another company that sees the value of NSF certification is the Shyang Yih Hardware Factory' which earned the mark last year. "NSF standards require you to cut down your defect ratio' and thus improve quality'" says the company's chairman' Hung Ruei-mu. "One advantage of having NSF approval is that it enables you to participate in contract bidding."

Shyang Yih produces a wide range of metal parts associated with drinking water' including ball valves' pneumatic and hydraulic connectors' quick connectors' flanges' safety valves' water gauge valves' needle valves' water inlet T-joints' ball cocks' reverse osmosis parts' and faucets.

Hung notes that the strict NSF standards require lead substances to be limited to a harmless level of under 0.025 PPM. Inspections of work pieces and sample products to ensure that the company is maintaining the required standards are not cheap' costing at least NT$300'000 (US$9'100) each. The tests are conducted at NSF's U.S. headquarters.

The company began making reverse osmosis parts and other parts for drinking-water equipment three years ago as part of its plan to break away from the crowding and intense competition in the market for hydraulic and pneumatic parts' which now are supplied mostly by mainland Chinese manufacturers. "As parts associated with drinking water require higher safety standards'" Hung explains' "their added-value must also be higher than that of hydraulic and pneumatic parts."

Parts for reverse osmosis equipment and drinking water machines currently account for 80% of the company's sales' with hydraulic and pneumatic parts making up the remaining 20%. Hung claims to supply the widest range of faucet types (encompassing almost 95% of all types available on the market)' and to be among Taiwan's top three suppliers of faucets in terms of volume.

Several of the faucets developed by Shyang Yih over the past three years are protected by patents' including one which is notable for its replaceable rubber water-control structure. This allows these faucets' unlike others' to be repaired instead of having to be replaced entirely once the water-control mechanism wears out.

Hung notes that Taiwan's manufacturers learned how to manufacture reverse osmosis parts from American suppliers' and have emerged as the world's best contract suppliers of such products. "Some suppliers in the line are coming up in mainland China'" the chairman concedes' "but they are no threat to us because their quality is still not very good."

Hung himself has invested in a factory in mainland China to supply the huge domestic market there. The mainland factory turns out 10'000 drinking water machine faucets and 10'000 reverse osmosis faucets a month. (Feb. 2004)

©1995-2006 Copyright China Economic News Service All Rights Reserved.