Taiwan's Plug, Socket, and Switch Makers Prosper With High-end Products

Oct 11, 2004 Ι Industry News Ι Electronics and Computers Ι By Quincy, CENS

Riding the crest of Taiwan's high-flying electronics industry, the island's makers of plugs, sockets, and switches have enjoyed good sales in recent years as they have constantly widened their technological edge and expanded into high-margin niche markets.

Many of their gains have come through a concentration on product innovation, which has enabled them to escape the cut-throat competition initiated by low-price, lesser-quality rivals (mainly in mainland China) and win an increasing number of contract orders from the big international companies, of which more and more are choosing to outsource key parts for their products.

Like most other manufacturers in Taiwan, local makers of switches, plugs, and sockets in general rely on original equipment/design manufacturing (OEM/ODM) orders from foreign customers, especially from the United States and Europe. This situation does not seem likely to change soon, since much of the island's industry is made up of small and medium-sized companies that lack the resources to develop their own product brands. Some producers in the line, however, do have the experience and know-how they need to start doing so.

Some makers have followed Taiwanese manufacturers in other lines to set up production in mainland China, both to take advantage of the lower production costs there and to be close to the Taiwanese-invested electronics companies. Others have opted to remain in Taiwan, focusing on high-margin items instead of competing on price.

Supplying Major Brands

One of the companies staying at home is Yeu Tsang Co., Ltd. An experienced manufacturer that specialized in designing and producing high-quality DIN plugs and jacks for CD power and audio-video (A/V) applications.

A strong development capability allows Yeu Tsang to offer a wide range of other products as well, including auto cigarette sockets and plugs, scart plugs and sockets, banana plugs and sockets, and BNC plugs and sockets.

Sky Shih, the company's president, claims that Yeu Tsang uses the most advanced equipment, including 12 computerized numerically controlled (CNC) lathes for copper pin making, as well as five plastic injection machines.

The firm is a long-term contract developer and manufacturer of connectors for major international brands, as well as for most of the leading information technology (IT) and electronics suppliers in Taiwan. This history has given Yeu Tsang an abundant store of experience in designing and making high-end products of the latest specifications.

"Our core competitiveness lies in our product quality being parallel with that of Europe and Japan, while our prices are only one third of theirs," Shih asserts. "Yeu Tsang plays a vital role in connecting signals and power between different computer parts and peripherals, and A/V and electronic products. Our customers, who are mainly big international computer and electronics brands, pass their design prints to us and commission us to make the actual products. Reliability is the determining factor in our long-term relations with those customers, because even the tiniest problem can affect product introduction schedules and, more importantly, the proper operation of the new products."

Shih says that his company is receiving an increasing number of orders that big international customers are giving it back after trying to switch to low-priced suppliers in mainland China, and finding that the resulting products had quality problems. "Yeu Tsang insists on manufacturing in Taiwan," the president comments, "despite the decline in orders that we have experienced in the past few years. We do this because we can't find qualified parts suppliers on the other side of the Taiwan Strait. Quality is the top priority for connector products, which are often miniature in size and demand the highest level of precision in every detail."

The company currently supplies over 1,500 product items and adds about 20 new ones to the list every year. It maintains a streamlined work force of only about 20. The majority of its products are exported to customers in Germany, the United Kingdom, France, and mainland China (where the buyers are mainly large Taiwan-based IT and electronics manufacturers).

New Functions

Another company that concentrates on the development and production of high-quality parts is San Shih Electrical Enterprise Co., Ltd. One of Taiwan's two top suppliers of surge protectors. The company boasts ISO-9000, UL, CS, CE, and PSE approval.

"R&D capability is one of the most important factors for success in this line," comments San Shih's vice president, Joe Wang. "Survival in this highly competitive industry is closely related to the designs and functions of new products, which often have a market life of no more than 18 months."

With its strong development capability, San Shih is able to supply a full range of surge protectors from power ratings of 110/120V to 220/250V and outlets numbering from four to 10. The products incorporate numerous new and convenient functions, such as digital timers and remotely control on/off.

The company has a mainland Chinese factory with 1,800 workers and a monthly capacity of about 1.5 million units. Company headquarters and R&D department, however, are kept in Taiwan.

"In addition to new appearance and new functions," Wang notes, "safety and quality are the major concerns of surge-protector buyers worldwide. For manufacturers, too, these are the two most important priorities, because a single family might use several of the devices and even a tiny defect in quality can cause serious damage after long-term use."

To maintain the highest quality standards, the company maintains an in-house UL and CSA certification laboratory that boasts the same testing and certification capabilities as the headquarters of those two organizations. Only the three top surge protector makers have such in-house capability, Wang says.

San Shih develops new products constantly in order to lead market trends and assure reasonable profit margins. It recently introduced an innovative new surge protector with a master-slave control function, developed to meet the multi-plug requirements of modern computer users. The new model is switched on and off via a universal serial bus (USB) cable connected to a PC, and can switch off all the peripherals (on slave outlets) at the same time as the PC's power is turned off.

Another new product is a surge protector with a patented built-in safety mechanism to prevent electrical shocks to users, especially children. An object with a single pin-a screwdriver or metal plate, for instance-cannot be plugged into the outlet.

San Shih is a major supplier to big discount chains, such as Wal-Mart, K-mart, and Costco, as well as large 3C (computers, communications, and consumer electronics) chain stores worldwide. Most of its products are exported to the U.S., Europe, and Japan on an OEM/ODM basis.

High-end Exemplifier

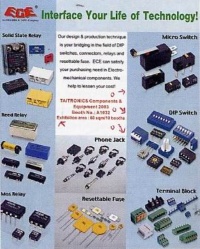

Yet another company that exemplifies the trend toward higher-end products is Excel Cell Electronic Co., Ltd. Which claims to be the No. 1 maker of dual inline package (DIP) switches in Taiwan. The company also turns out terminal blocks and relays, slide/push/micro switches, and both USB and IEEE 1394 connectors.

The firm's sales manager, Jimmy Huang, says that Excel Cell exports its DIP switches to the world's top brands for industrial machinery, instruments, security systems, and other products that require precision circuit control. A complete range of DIP switches is featured in the company's catalog, from one-pole (two-lead) to 12-pole (allowing 4,096 setting options) models in both through-hole and surface-mount-technology (SMT) types.

Huang reports that his company is engaged in developing smaller, lighter, and more functional switches. It recently introduced new piano-type (edge-actuated) DIP switch models, which are small, cost less to make, and are more functional than the general run of switches on the market.

Excel Cell has strong global competitiveness, Huang declares, because of its ability to design and produce most of the special production and testing equipment it needs, thereby improving production efficiency and product quality. Top quality is further assured through a strict quality-control system.

Another competitive asset is the ability to integrate all aspects of the production process, from product design to manufacturing. This ability helps to cut costs and shorten delivery times. In addition, the company has been working to diversify its product line and provide the convenience of one-stop shopping to customers all over the world.

Established in 1981 and now boasting ISO-9001 and ISO-14001 certification, Excel Cell operates two plants and is preparing to put a third on-line soon. The first plant, in central Taiwan, has 350 employees (including about 30 R&D specialists) and produces mainly new high-end items with high margins. The second plant, in Guangdong Province, mainland China, has 200 workers and turns out mostly standard and large-volume items. The third plant, in Jiangsu Province, will begin mass production late this year or early in 2005.

The company is currently able to produce a total of seven to 10 million DIP switches per month, about 60% of which is exported to markets in Asia, Europe, and the U.S. DIP switches account for around 65% of overall revenue, terminal block and relay products for another 25%, and other products such as sockets, USB and IEEE 1394 connectors, and modular plugs for the rest. (Aug. 2004)

Many of their gains have come through a concentration on product innovation, which has enabled them to escape the cut-throat competition initiated by low-price, lesser-quality rivals (mainly in mainland China) and win an increasing number of contract orders from the big international companies, of which more and more are choosing to outsource key parts for their products.

Like most other manufacturers in Taiwan, local makers of switches, plugs, and sockets in general rely on original equipment/design manufacturing (OEM/ODM) orders from foreign customers, especially from the United States and Europe. This situation does not seem likely to change soon, since much of the island's industry is made up of small and medium-sized companies that lack the resources to develop their own product brands. Some producers in the line, however, do have the experience and know-how they need to start doing so.

Some makers have followed Taiwanese manufacturers in other lines to set up production in mainland China, both to take advantage of the lower production costs there and to be close to the Taiwanese-invested electronics companies. Others have opted to remain in Taiwan, focusing on high-margin items instead of competing on price.

Supplying Major Brands

One of the companies staying at home is Yeu Tsang Co., Ltd. An experienced manufacturer that specialized in designing and producing high-quality DIN plugs and jacks for CD power and audio-video (A/V) applications.

A strong development capability allows Yeu Tsang to offer a wide range of other products as well, including auto cigarette sockets and plugs, scart plugs and sockets, banana plugs and sockets, and BNC plugs and sockets.

Sky Shih, the company's president, claims that Yeu Tsang uses the most advanced equipment, including 12 computerized numerically controlled (CNC) lathes for copper pin making, as well as five plastic injection machines.

The firm is a long-term contract developer and manufacturer of connectors for major international brands, as well as for most of the leading information technology (IT) and electronics suppliers in Taiwan. This history has given Yeu Tsang an abundant store of experience in designing and making high-end products of the latest specifications.

"Our core competitiveness lies in our product quality being parallel with that of Europe and Japan, while our prices are only one third of theirs," Shih asserts. "Yeu Tsang plays a vital role in connecting signals and power between different computer parts and peripherals, and A/V and electronic products. Our customers, who are mainly big international computer and electronics brands, pass their design prints to us and commission us to make the actual products. Reliability is the determining factor in our long-term relations with those customers, because even the tiniest problem can affect product introduction schedules and, more importantly, the proper operation of the new products."

Shih says that his company is receiving an increasing number of orders that big international customers are giving it back after trying to switch to low-priced suppliers in mainland China, and finding that the resulting products had quality problems. "Yeu Tsang insists on manufacturing in Taiwan," the president comments, "despite the decline in orders that we have experienced in the past few years. We do this because we can't find qualified parts suppliers on the other side of the Taiwan Strait. Quality is the top priority for connector products, which are often miniature in size and demand the highest level of precision in every detail."

The company currently supplies over 1,500 product items and adds about 20 new ones to the list every year. It maintains a streamlined work force of only about 20. The majority of its products are exported to customers in Germany, the United Kingdom, France, and mainland China (where the buyers are mainly large Taiwan-based IT and electronics manufacturers).

New Functions

Another company that concentrates on the development and production of high-quality parts is San Shih Electrical Enterprise Co., Ltd. One of Taiwan's two top suppliers of surge protectors. The company boasts ISO-9000, UL, CS, CE, and PSE approval.

"R&D capability is one of the most important factors for success in this line," comments San Shih's vice president, Joe Wang. "Survival in this highly competitive industry is closely related to the designs and functions of new products, which often have a market life of no more than 18 months."

With its strong development capability, San Shih is able to supply a full range of surge protectors from power ratings of 110/120V to 220/250V and outlets numbering from four to 10. The products incorporate numerous new and convenient functions, such as digital timers and remotely control on/off.

The company has a mainland Chinese factory with 1,800 workers and a monthly capacity of about 1.5 million units. Company headquarters and R&D department, however, are kept in Taiwan.

"In addition to new appearance and new functions," Wang notes, "safety and quality are the major concerns of surge-protector buyers worldwide. For manufacturers, too, these are the two most important priorities, because a single family might use several of the devices and even a tiny defect in quality can cause serious damage after long-term use."

To maintain the highest quality standards, the company maintains an in-house UL and CSA certification laboratory that boasts the same testing and certification capabilities as the headquarters of those two organizations. Only the three top surge protector makers have such in-house capability, Wang says.

San Shih develops new products constantly in order to lead market trends and assure reasonable profit margins. It recently introduced an innovative new surge protector with a master-slave control function, developed to meet the multi-plug requirements of modern computer users. The new model is switched on and off via a universal serial bus (USB) cable connected to a PC, and can switch off all the peripherals (on slave outlets) at the same time as the PC's power is turned off.

Another new product is a surge protector with a patented built-in safety mechanism to prevent electrical shocks to users, especially children. An object with a single pin-a screwdriver or metal plate, for instance-cannot be plugged into the outlet.

San Shih is a major supplier to big discount chains, such as Wal-Mart, K-mart, and Costco, as well as large 3C (computers, communications, and consumer electronics) chain stores worldwide. Most of its products are exported to the U.S., Europe, and Japan on an OEM/ODM basis.

High-end Exemplifier

Yet another company that exemplifies the trend toward higher-end products is Excel Cell Electronic Co., Ltd. Which claims to be the No. 1 maker of dual inline package (DIP) switches in Taiwan. The company also turns out terminal blocks and relays, slide/push/micro switches, and both USB and IEEE 1394 connectors.

The firm's sales manager, Jimmy Huang, says that Excel Cell exports its DIP switches to the world's top brands for industrial machinery, instruments, security systems, and other products that require precision circuit control. A complete range of DIP switches is featured in the company's catalog, from one-pole (two-lead) to 12-pole (allowing 4,096 setting options) models in both through-hole and surface-mount-technology (SMT) types.

Huang reports that his company is engaged in developing smaller, lighter, and more functional switches. It recently introduced new piano-type (edge-actuated) DIP switch models, which are small, cost less to make, and are more functional than the general run of switches on the market.

Excel Cell has strong global competitiveness, Huang declares, because of its ability to design and produce most of the special production and testing equipment it needs, thereby improving production efficiency and product quality. Top quality is further assured through a strict quality-control system.

Another competitive asset is the ability to integrate all aspects of the production process, from product design to manufacturing. This ability helps to cut costs and shorten delivery times. In addition, the company has been working to diversify its product line and provide the convenience of one-stop shopping to customers all over the world.

Established in 1981 and now boasting ISO-9001 and ISO-14001 certification, Excel Cell operates two plants and is preparing to put a third on-line soon. The first plant, in central Taiwan, has 350 employees (including about 30 R&D specialists) and produces mainly new high-end items with high margins. The second plant, in Guangdong Province, mainland China, has 200 workers and turns out mostly standard and large-volume items. The third plant, in Jiangsu Province, will begin mass production late this year or early in 2005.

The company is currently able to produce a total of seven to 10 million DIP switches per month, about 60% of which is exported to markets in Asia, Europe, and the U.S. DIP switches account for around 65% of overall revenue, terminal block and relay products for another 25%, and other products such as sockets, USB and IEEE 1394 connectors, and modular plugs for the rest. (Aug. 2004)

©1995-2006 Copyright China Economic News Service All Rights Reserved.