Local Producers Face Squeeze on Margins

Mar 26, 2004 Ι Industry News Ι Furniture Ι By Ben, CENS

Over the past year, Taiwan's producers of metal furniture have found themselves between a rock and a hard place. On one side, local producers have been hit by a 40% surge in the prices of iron and steel--key materials used in their products--while on the other side fierce competition from rivals in Asia's developing economies has limited their room to raise prices in order to recoup the higher costs.

In fact, the competition from low-cost rivals has been a headache for local industry players for several years. In order to compete with the newcomers on an equal cost footing, many Taiwanese manufacturers of metal furniture have moved their production lines to mainland China and various Southeast Asian nations.

For companies that have stuck it out in Taiwan, the main strategy for survival has been to develop high-end products for lucrative niche markets. Producers are also focusing on product areas in which Taiwan has a clear advantage, such as electroplated metal furniture. One industry insider claims that mainland manufacturers are still years behind Taiwan in this field.

Cross-Strait Production

Good Faith Furniture Co., Ltd., established in 1991, produces metal furniture on both sides of the Taiwan Strait. Its electroplated products are made mainly in Taiwan, while its enamel-baked models are made in mainland China.

"Taiwan is still an ideal place to produce electroplated furniture because of the strong ability of domestic firms specializing in high-quality electroplating surface treatment," says Good Faith president Chen Cheng-hui. "But we cannot compete with mainland counterpart firms specializing in enamel-baked furniture because they have learned how to produce such products at low costs. That's why we have kept our electroplated furniture production in Taiwan and moved production of enamel-baked furniture to the mainland."

At present, the company makes enamel-baked furniture in mainland China in cooperation with a local enamel specialist. The partnership frees up money that would have gone into production equipment for use in expanding the company's facilities in Taiwan, Chen says.

Chen says that his company has a highly experienced team in charge of product development to support its original design business. The company also accepts original equipment manufacturing (OEM) orders based on customer designs.

While Good Faith's business has risen with the global economy in recent times, Chen says that higher material costs have taken a toll on profit margins.

To reverse the slide, the company is stepping up investment in higher margin products, including a new line of metal living-room furniture. The company plans to roll out the new line in March this year.

Good Faith currently exports all of its products, mainly to the U.S., Europe and the Middle East. The company says the majority of its output is directly shipped to foreign importers.

To attract more international buyers, Good Faith will take part in several well-known international furniture shows, including shows in Singapore and Dubai in March and October, respectively.

K/D Specialist

Chang Kuan Enterprise Co., Ltd. Manufactures high-quality iron-pipe K/D furniture, including clothes hangers, end tables and dining sets, at its factory in Taiwan. At present, clothes hangers and end tables account for the bulk the company's total output, all of which is exported to Europe, Japan and other overseas markets.

Chang Kuan can also serve customers seeking direct shipment from mainland China.

"My elder brother has a plant in the mainland that specializes in the same products that our plant makes in Taiwan," says Lee Chun-te, president of the company. "If our customers request direct shipments from the mainland, we can satisfy their demand with the assistance of my brother's plant."

Chang Kuan specializes in bending iron pipes, electroplating and enamel baking surface treatment in a variety of colors. The company recently introduced a series of clothes hangers in four colors. Lee says the new line has received a warm welcome from customers due to their stylish and versatile design. The new hangers come with an attached disk for storing keys and other small objects.

Keeping Pace With the Market

Phoebe & George Enterprise Co., a manufacturer of K/D metal furniture and computer desks, has gradually expanded the use of composite materials in its products to meet changing global demand. The company has also been introducing profitable and stylish new product lines, including metal bedroom sets, over the past year.

Iron piping is the main material used in the company's coffee tables, end tables, dining sets, and bedroom sets, but wood, glass, and other materials are also being given bigger roles in such metal furniture products.

In the past, Phoebe & George has concentrated on the U.S. market. Over the past one year, however, it has made inroads into the European market on the strength of several big-ticket orders from buyers there. The company plans to enhance the production of European-style products in the next few years to tap the new market.

"European-style coffee tables have strong structures and simple contours," says company president George Kao. "We will increase production of such items this year.

Two years ago, Phoebe & George added a hot-selling line of bar stools to its product offering, and last year it began production of bedroom sets with promising prospects in the European market, says Kao.

Six years ago, the company set up its first mainland China plant in Guangdong Province. The company now operates three plants in the mainland, with a total production space of 30,000 square meters. Two of the plants were established last year to turn out new products and meet the influx of orders from Europe. The two new facilities have boosted the company's production capacity by 1.5-fold from the level of a year ago.

Despite the shift of production to mainland China, Phoebe & George still procures high-grade iron and steel from Taiwan's China Steel Corp. "Most iron and steel materials made in the mainland are not reliable," Kao says. "Since we target the upper market, we have to use high-quality materials to win the long-term confidence of our customers."

In addition to the adoption of high-quality materials, the company has also implemented a stringent quality control (QC) system at its factories.

In addition to its self-designed products, Phoebe & George welcomes orders on OEM and original design manufacturer (ODM) terms. The company has seen a substantial increase in OEM orders over the past year, Kao says. "We especially welcome OEM orders because they can help us achieve steady growth in the foreseeable future."

Kao says his company is seeking to form partnerships with overseas furniture manufacturers to develop innovative products for worldwide sale.

Olympics Supplier

Wok & Pan Industry Inc. Management claims the firm was the sole official Asian supplier of tables and chairs for the 2000 Sydney Olympic Games. The company started manufacturing operations in Taiwan in 1988, and in 1994 moved its production facility to Shenzhen in Guangdong Province, mainland China, to reduce costs.

Wok & Pan's mainland plant occupies 30,000 square meters and employs more than 400 workers, including a product-development team.

To keep its quality high, the company has implemented a strict QC system and continually seeks ways to further hone its production standards, says M.C. Tsai, president of the company.

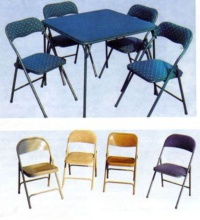

Wok & Pan mainly supplies folding banquet tables, computer tables, K/D meeting tables, rental banquet tables, eight-foot folding tables, Japanese tables, and plastic-top tables.

Tsai says his company's mainland plant can handle molding, pressing, welding, polishing, coating, assembling, packing, stamping, and testing. "Through integrated production, we can guarantee the high quality of our products," he says.

The company currently has three automated production lines. At present, the company is capable of exporting 1.5 million furniture items per year. Most of its output is sold to major home centers and chain store, such as Home Depot, Office Depot, and Dollar General.

Banquet tables are among Wok & Pan's hottest selling items. Such items feature high-grade material tops, such as particleboards imported from Belgium and Italy and melamine board from Malaysia.

In fact, the competition from low-cost rivals has been a headache for local industry players for several years. In order to compete with the newcomers on an equal cost footing, many Taiwanese manufacturers of metal furniture have moved their production lines to mainland China and various Southeast Asian nations.

For companies that have stuck it out in Taiwan, the main strategy for survival has been to develop high-end products for lucrative niche markets. Producers are also focusing on product areas in which Taiwan has a clear advantage, such as electroplated metal furniture. One industry insider claims that mainland manufacturers are still years behind Taiwan in this field.

Cross-Strait Production

Good Faith Furniture Co., Ltd., established in 1991, produces metal furniture on both sides of the Taiwan Strait. Its electroplated products are made mainly in Taiwan, while its enamel-baked models are made in mainland China.

"Taiwan is still an ideal place to produce electroplated furniture because of the strong ability of domestic firms specializing in high-quality electroplating surface treatment," says Good Faith president Chen Cheng-hui. "But we cannot compete with mainland counterpart firms specializing in enamel-baked furniture because they have learned how to produce such products at low costs. That's why we have kept our electroplated furniture production in Taiwan and moved production of enamel-baked furniture to the mainland."

At present, the company makes enamel-baked furniture in mainland China in cooperation with a local enamel specialist. The partnership frees up money that would have gone into production equipment for use in expanding the company's facilities in Taiwan, Chen says.

Chen says that his company has a highly experienced team in charge of product development to support its original design business. The company also accepts original equipment manufacturing (OEM) orders based on customer designs.

While Good Faith's business has risen with the global economy in recent times, Chen says that higher material costs have taken a toll on profit margins.

To reverse the slide, the company is stepping up investment in higher margin products, including a new line of metal living-room furniture. The company plans to roll out the new line in March this year.

Good Faith currently exports all of its products, mainly to the U.S., Europe and the Middle East. The company says the majority of its output is directly shipped to foreign importers.

To attract more international buyers, Good Faith will take part in several well-known international furniture shows, including shows in Singapore and Dubai in March and October, respectively.

K/D Specialist

Chang Kuan Enterprise Co., Ltd. Manufactures high-quality iron-pipe K/D furniture, including clothes hangers, end tables and dining sets, at its factory in Taiwan. At present, clothes hangers and end tables account for the bulk the company's total output, all of which is exported to Europe, Japan and other overseas markets.

Chang Kuan can also serve customers seeking direct shipment from mainland China.

"My elder brother has a plant in the mainland that specializes in the same products that our plant makes in Taiwan," says Lee Chun-te, president of the company. "If our customers request direct shipments from the mainland, we can satisfy their demand with the assistance of my brother's plant."

Chang Kuan specializes in bending iron pipes, electroplating and enamel baking surface treatment in a variety of colors. The company recently introduced a series of clothes hangers in four colors. Lee says the new line has received a warm welcome from customers due to their stylish and versatile design. The new hangers come with an attached disk for storing keys and other small objects.

Keeping Pace With the Market

Phoebe & George Enterprise Co., a manufacturer of K/D metal furniture and computer desks, has gradually expanded the use of composite materials in its products to meet changing global demand. The company has also been introducing profitable and stylish new product lines, including metal bedroom sets, over the past year.

Iron piping is the main material used in the company's coffee tables, end tables, dining sets, and bedroom sets, but wood, glass, and other materials are also being given bigger roles in such metal furniture products.

In the past, Phoebe & George has concentrated on the U.S. market. Over the past one year, however, it has made inroads into the European market on the strength of several big-ticket orders from buyers there. The company plans to enhance the production of European-style products in the next few years to tap the new market.

"European-style coffee tables have strong structures and simple contours," says company president George Kao. "We will increase production of such items this year.

Two years ago, Phoebe & George added a hot-selling line of bar stools to its product offering, and last year it began production of bedroom sets with promising prospects in the European market, says Kao.

Six years ago, the company set up its first mainland China plant in Guangdong Province. The company now operates three plants in the mainland, with a total production space of 30,000 square meters. Two of the plants were established last year to turn out new products and meet the influx of orders from Europe. The two new facilities have boosted the company's production capacity by 1.5-fold from the level of a year ago.

Despite the shift of production to mainland China, Phoebe & George still procures high-grade iron and steel from Taiwan's China Steel Corp. "Most iron and steel materials made in the mainland are not reliable," Kao says. "Since we target the upper market, we have to use high-quality materials to win the long-term confidence of our customers."

In addition to the adoption of high-quality materials, the company has also implemented a stringent quality control (QC) system at its factories.

In addition to its self-designed products, Phoebe & George welcomes orders on OEM and original design manufacturer (ODM) terms. The company has seen a substantial increase in OEM orders over the past year, Kao says. "We especially welcome OEM orders because they can help us achieve steady growth in the foreseeable future."

Kao says his company is seeking to form partnerships with overseas furniture manufacturers to develop innovative products for worldwide sale.

Olympics Supplier

Wok & Pan Industry Inc. Management claims the firm was the sole official Asian supplier of tables and chairs for the 2000 Sydney Olympic Games. The company started manufacturing operations in Taiwan in 1988, and in 1994 moved its production facility to Shenzhen in Guangdong Province, mainland China, to reduce costs.

Wok & Pan's mainland plant occupies 30,000 square meters and employs more than 400 workers, including a product-development team.

To keep its quality high, the company has implemented a strict QC system and continually seeks ways to further hone its production standards, says M.C. Tsai, president of the company.

Wok & Pan mainly supplies folding banquet tables, computer tables, K/D meeting tables, rental banquet tables, eight-foot folding tables, Japanese tables, and plastic-top tables.

Tsai says his company's mainland plant can handle molding, pressing, welding, polishing, coating, assembling, packing, stamping, and testing. "Through integrated production, we can guarantee the high quality of our products," he says.

The company currently has three automated production lines. At present, the company is capable of exporting 1.5 million furniture items per year. Most of its output is sold to major home centers and chain store, such as Home Depot, Office Depot, and Dollar General.

Banquet tables are among Wok & Pan's hottest selling items. Such items feature high-grade material tops, such as particleboards imported from Belgium and Italy and melamine board from Malaysia.

©1995-2006 Copyright China Economic News Service All Rights Reserved.